Custom Solutions for

Unique Challenges.

Our Mission

We engineer custom solutions for unique manufacturing challenges to bring intelligent precision to critical tasks that require more than just mechanical repetition.

Our Vision

A future where advanced robotics, machine vision, and automation are accessible for industries of any size.

Engineering Expertise

Machine Vision

Smart cameras and sensors for defect detection, visual alignment, and sorting using machine vision & AI.

Industrial PLC & SCADA

Full-stack automation using PLC, SCADA architecture, and field instrument integration for heavy industry.

Embedded Systems

Custom PCB design and micro-controller boards that eliminate the bulk and expense of generic PLCs.

Power Electronics

Custom inverter drivers, SPWM implementation, and analog circuit design for specialized voltage or efficiency requirements.

Mechanical Design

End-to-end development of custom machinery, 3D modeling, and fabrication of 3D printed parts.

Closed-Loop Control

PID and motion algorithms for applications requiring high-speed stability and precise positioning.

Project Insights

Behind the scenes of our deployed custom engineering solutions.

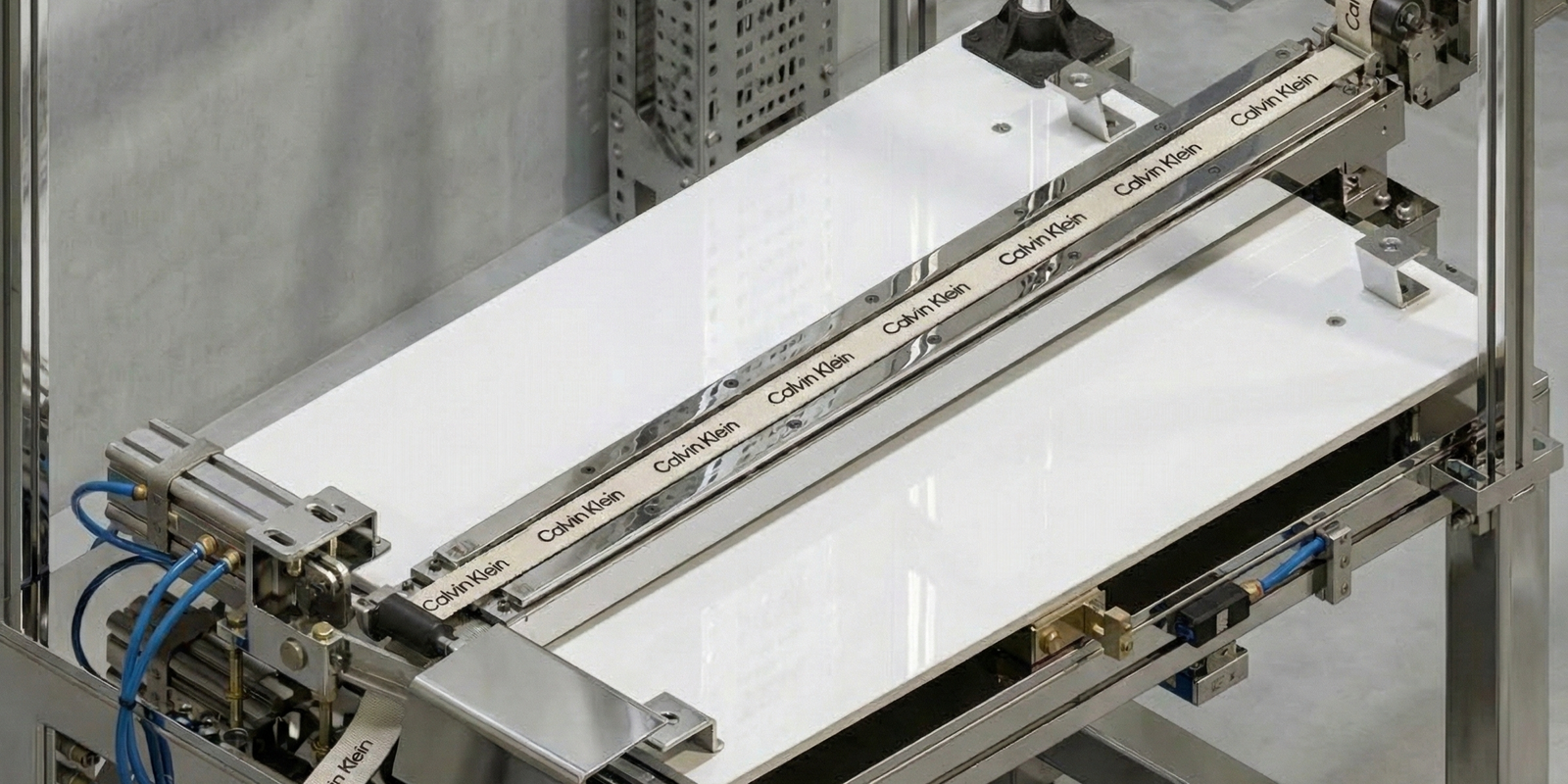

Vision-Guided Precision Cutter

Industrial AutomationThe Challenge

Cutting elastic waistbands to precise lengths while compensating for complex material stretch.

The Solution

A closed-loop system integrating Machine Vision with PID control. We utilized a Samkoon PLC and Xinjie Servo System to dynamically adjust cutter timing based on real-time visual feedback.

Key Outcome

Increased process speed by 100% and improved accuracy by 86% compared to manual labor.

Adhesive Dispensing Robot Control System

Robotics & CNCThe Challenge

Developing a custom control system for a 3-axis Cartesian robot to dispense adhesive dots following complex DXF patterns.

The Solution

Engineered a cost-effective controller using Raspberry Pi and ESP32 running FluidNC. Wrote custom Python middleware to parse DXF files directly into G-code trajectories.

Key Outcome

Delivered advanced CNC functionality and custom pattern generation at a fraction of the cost of commercial dispensing robots.

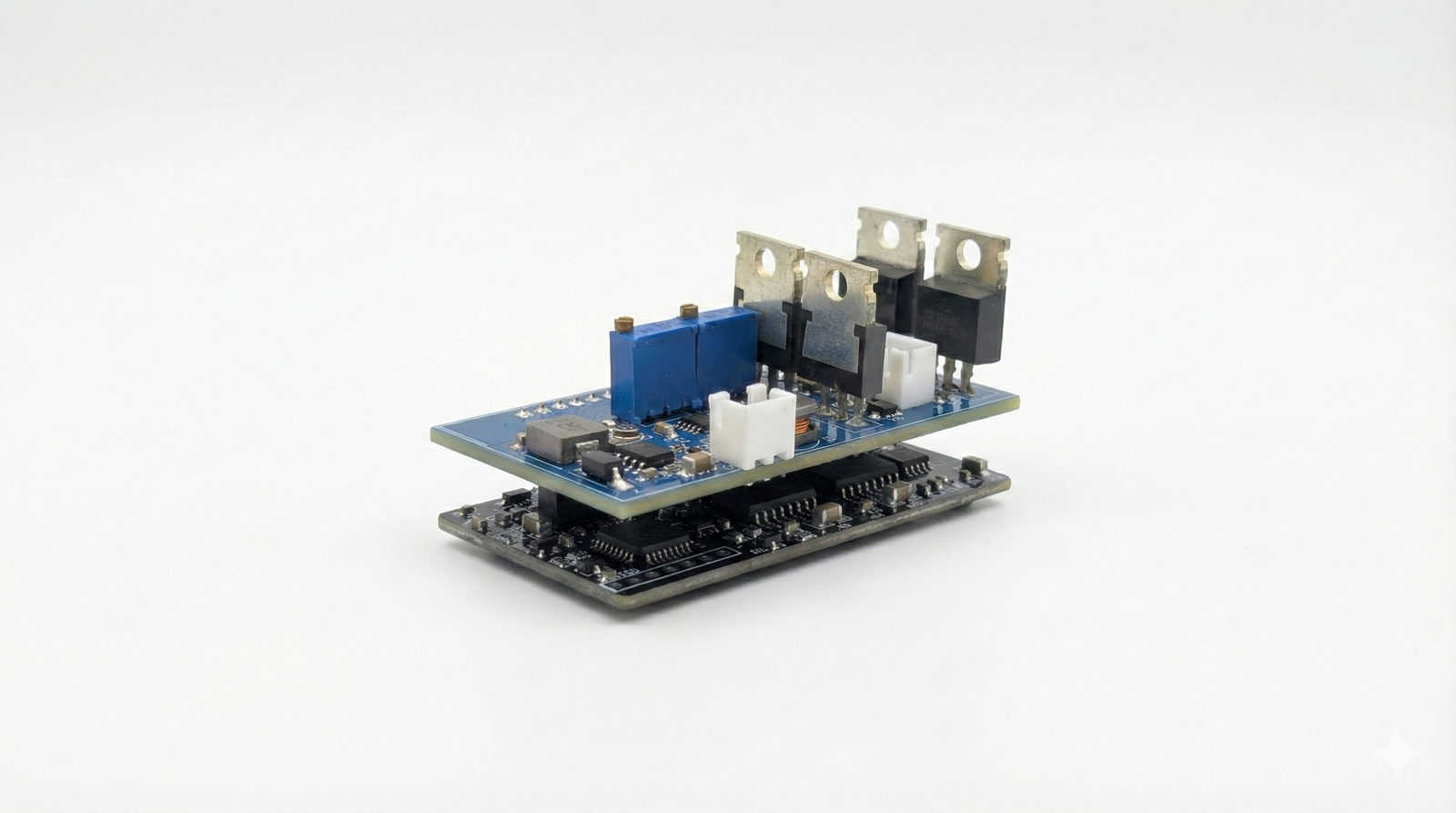

Custom Synchronous Motor Driver

Power ElectronicsThe Challenge

Reducing ventilation operational costs in trains by converting stationary fans to oscillating fans running on a specialized 110 VDC supply.

The Solution

Designed a custom Sinusoidal Pulse Wave Modulation (SPWM) inverter driver from scratch. Handled the analog circuit design and PCB layout (KiCad) to handle the specific voltage requirements.

Key Outcome

Successfully enabled the retrofit of efficient oscillating fans, significantly reducing long-term energy consumption.

IoT Pressure Monitoring System

Industrial IoTThe Challenge

Lack of visibility into pneumatic ring pressure levels made maintenance investigative activities difficult and reactive.

The Solution

Developed a wireless monitoring node using ESP32 to log real-time pressure data directly to Google Sheets via HTTP, creating a low-cost, accessible dashboard.

Key Outcome

Provided accurate data for root-cause analysis and sparked a factory-wide initiative for automated data collection.

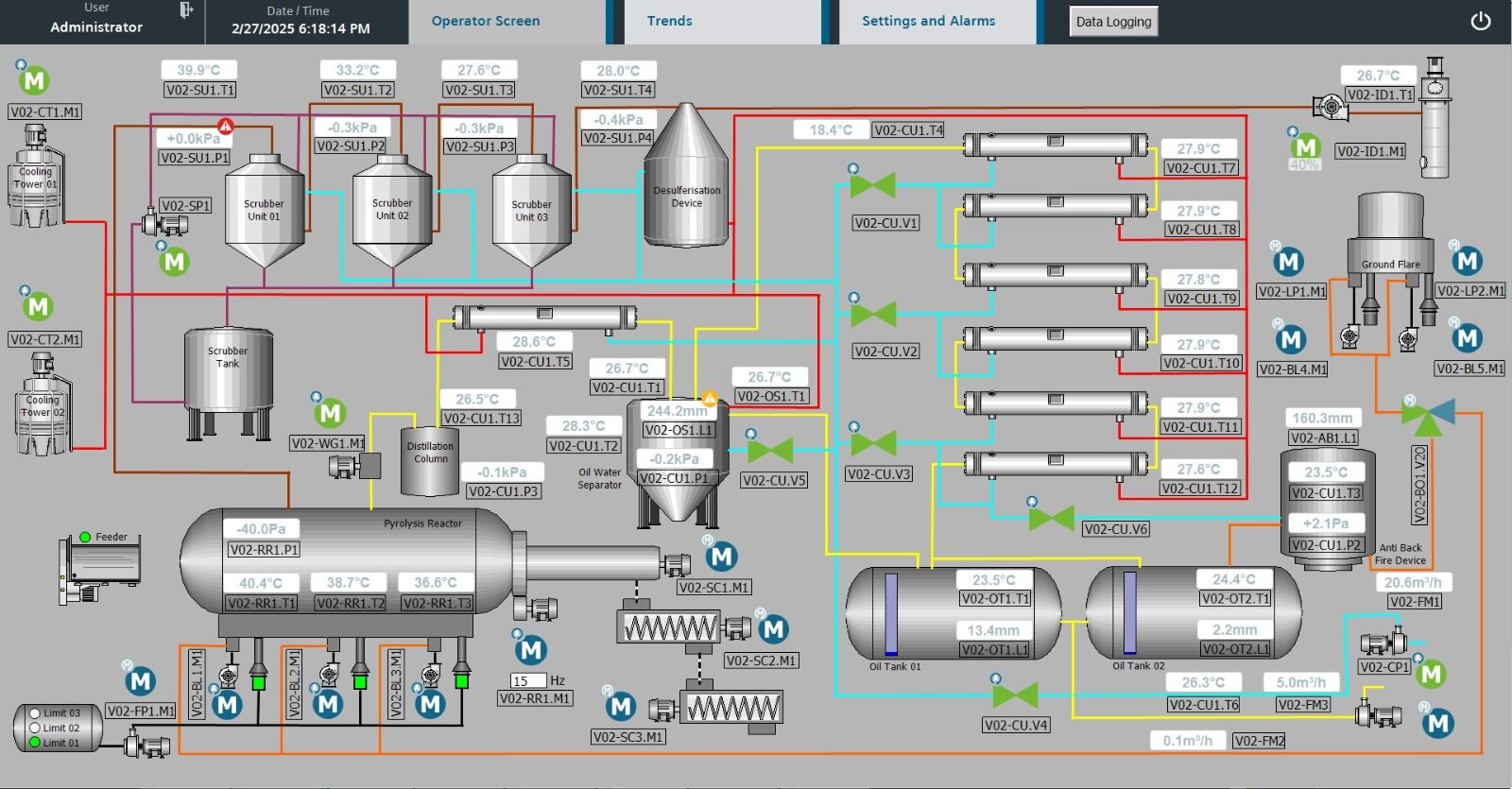

Pyrolysis Plant Automation

Heavy Industry (INSEE)The Challenge

Commissioning a full-scale automation system for a Pyrolysis Plant, requiring robust industrial reliability and complex system integration.

The Solution

Developed and commissioned a Siemens S7-1500 PLC architecture with a SCADA system on a Rack PC. Handled full-stack PLC programming, field instrument integration, and rigorous acceptance testing.

Key Outcome

Successful plant commissioning, ensuring high-availability operation and seamless data visualization.

Innovation Lab

Current research and development initiatives pushing the boundaries of what's possible.

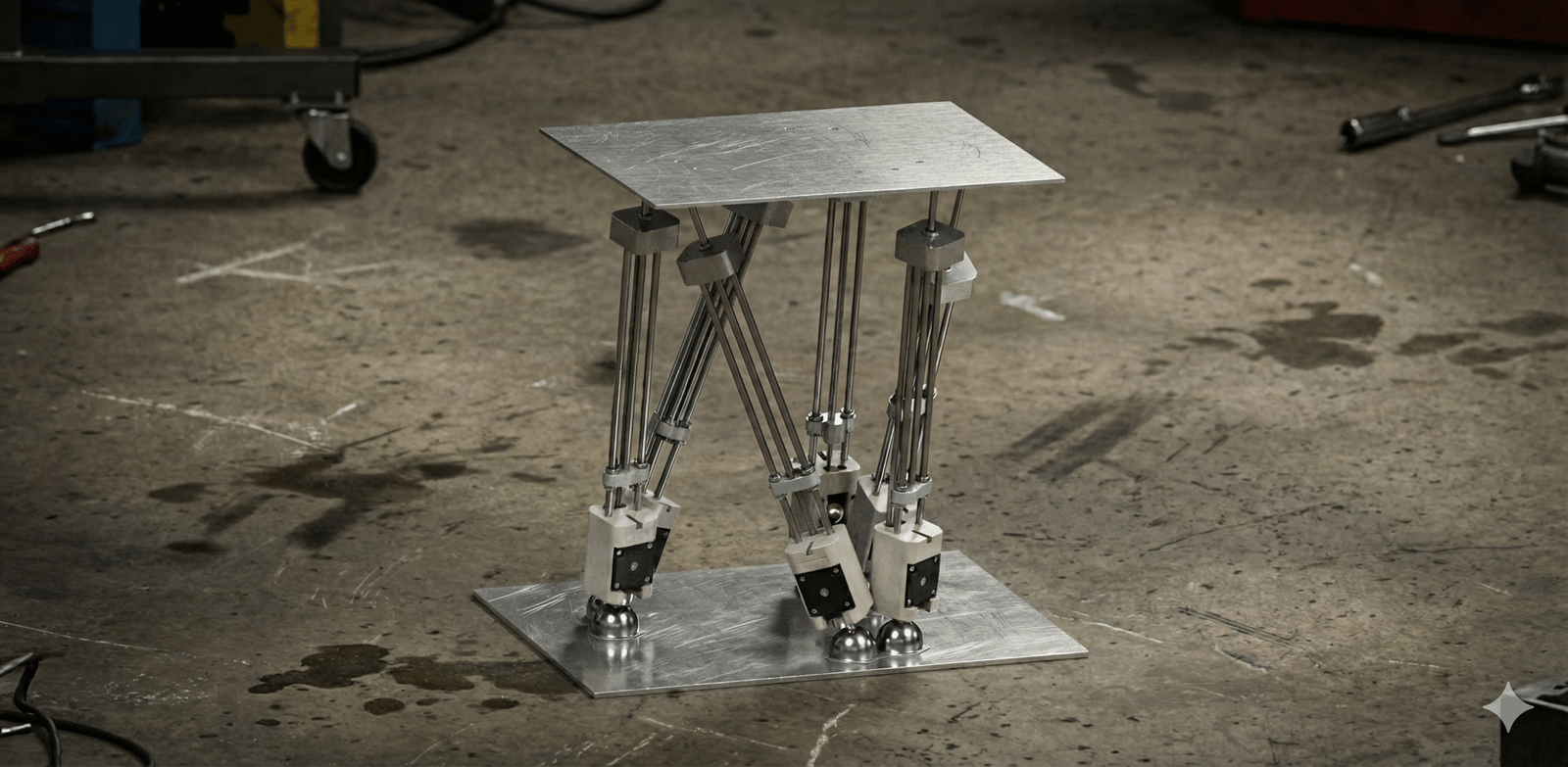

High-Dynamic 6-DOF Platform

Robotics & SimulationThe Objective

Designing a low-inertia Stewart Platform capable of high-frequency response for advanced simulation tasks.

The Hypothesis

Replacing traditional screw drives with belt-actuated linear actuators will significantly minimize friction and moving mass, improving dynamic range.

Current Status

Validating Mechanical Architecture.

INTEGRATING CONTROL SOFTWARE

AI-Powered Surface Inspection

AI & OpticsThe Objective

Automating quality control for "boundary laminated fabric accessories" where defects are subtle and datasets are scarce.

The Hypothesis

A custom Random Forest Classifier using pixel-level semantic segmentation can achieve high accuracy (99.95%) on mobile-grade processors without deep learning overhead.

Current Status

Prototype Deployed & Validated.

REFINING HARDWARE

The Engineering Roadmap

Audit

We analyze your workflow to identify the root bottleneck. We define the problem clearly before writing a single line of code.

Sprint

We move fast. Using our in-house 3D printing and electronics lab, we build a functional Proof of Concept (PoC) to validate the solution.

Pilot

We bring the prototype to your floor. Field testing ensures the solution works in the real world, not just in the lab.

Scale

With the concept proven, we engineer the final industrial system, handling fabrication, installation, and handover.

Stop Guessing. Start Testing.

We offer a structured Rapid Prototyping Sprint to validate your solution before you commit to full-scale production.